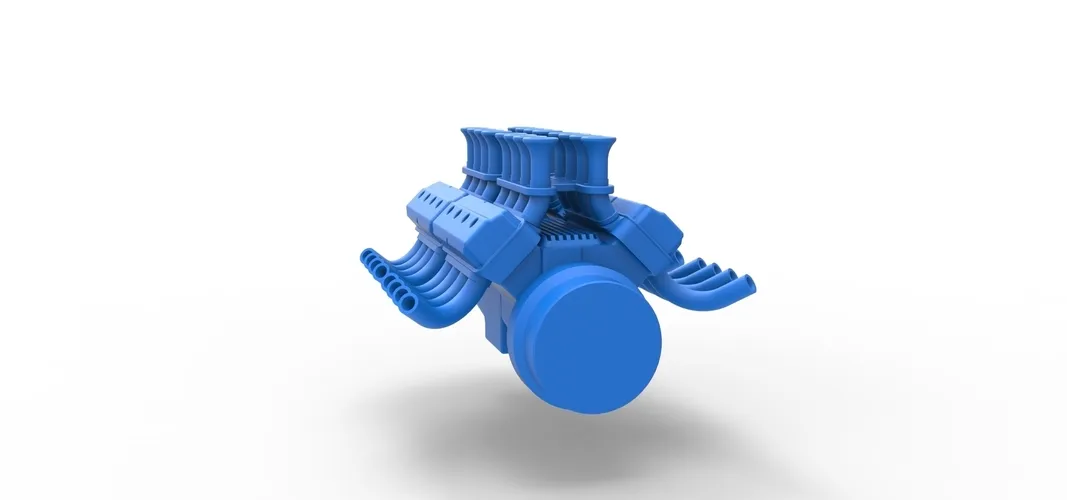

Diecast Engine: An Introduction

Diecast engines represent a fascinating blend of engineering, artistry, and the enduring allure of collecting. They are not merely toys but meticulously crafted miniature replicas of real-world engines, capturing the essence of automotive history and technological innovation in a tangible form. These models are prized by enthusiasts for their detail, accuracy, and the stories they tell. This article delves into the intriguing world of diecast engines, unveiling seven astonishing facts that will deepen your appreciation for these miniature marvels. From the materials used to create them to the techniques employed in their manufacture, and the vibrant community that surrounds them, we explore the key aspects that make diecast engines so captivating. Prepare to be amazed by the intricate processes and the rich history that lies within these small, yet significant, pieces of automotive art.

The Materials: What Are Diecast Engines Made Of?

The creation of a diecast engine is a feat of precision, beginning with carefully selected materials that ensure both durability and detail. The primary material used is typically a zinc alloy, a versatile and cost-effective choice for die-casting processes. This alloy allows for intricate designs and fine details, essential for capturing the complexity of an engine. In addition to the main alloy, other materials play crucial roles. Plastic components are used for elements like interior details, tires, and other non-metallic parts, offering flexibility in design and manufacturing. Glass or transparent plastic is often employed for windows and lights, providing a realistic appearance. Metal axles and screws ensure the structural integrity of the model. The combination of these materials allows manufacturers to achieve both aesthetic appeal and functional durability.

Zinc Alloy Explained

Zinc alloy, the backbone of most diecast engines, is an alloy primarily composed of zinc, along with small amounts of other metals such as aluminum, magnesium, and copper. This specific composition gives the alloy its unique properties. Zinc alloy’s low melting point makes it ideal for die-casting, allowing molten metal to flow into intricate molds and capture fine details. The addition of aluminum enhances strength and corrosion resistance, ensuring the models can withstand the test of time. Magnesium is added to improve fluidity during casting and reduces porosity. Copper contributes to the alloy’s strength and hardness. The final result is a material that provides a robust base for the engine, capable of holding its shape while allowing for intricate designs and detailed finishes. The properties of zinc alloy also make it ideal for replicating the weight and feel of a real engine, adding to the realism.

Other Materials Used

Beyond zinc alloy, various other materials contribute to the final product. Plastic components are extensively used for parts that require flexibility or cannot be easily replicated with metal, such as interior components, tires, and certain engine details. The selection of plastics is crucial, as they must be durable and capable of retaining their shape over time. Transparent plastics or glass are used for windows and lights, providing a realistic appearance and allowing for interior details to be visible. The paint used on diecast engines is another key material, designed to adhere well to the metal surface while offering a durable and vibrant finish. Decals and stickers are also employed to add intricate details like logos, badges, and markings. The integration of these diverse materials is a testament to the manufacturing skill and artistry, creating miniature replicas that are both accurate and visually compelling.

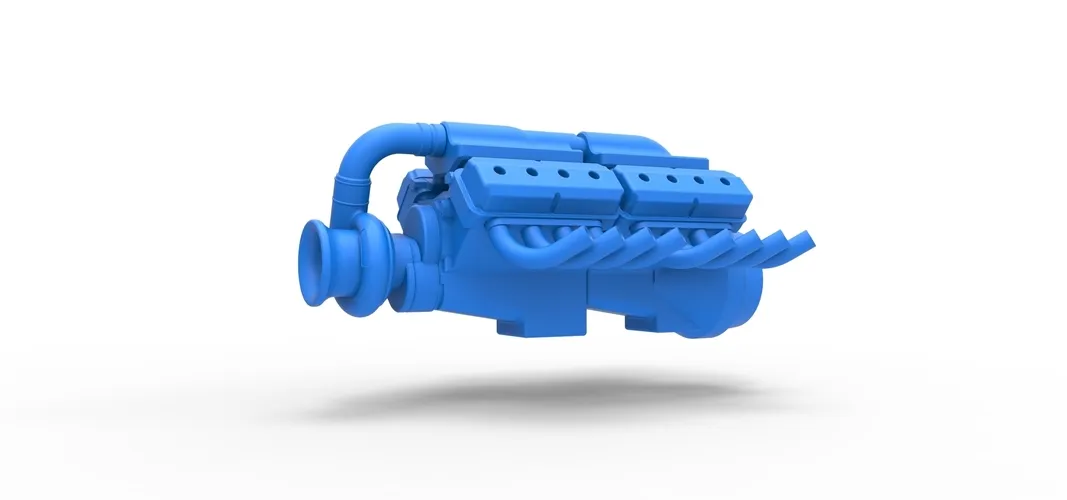

The Scale Factor: Size Matters in Diecast Engines

The scale of a diecast engine is crucial, directly influencing the level of detail and the overall visual impact of the model. Scales are ratios, indicating the relationship between the model’s dimensions and the actual engine’s dimensions. Common scales like 1:18, 1:24, and 1:43 offer varying levels of detail and different collecting experiences. The scale chosen by the manufacturer determines the size of the model and, consequently, the complexity of the features that can be realistically replicated. Larger scales, such as 1:18, provide ample space for intricate designs, allowing for highly detailed engines with functioning parts. Smaller scales, while offering less detail, often enable broader collections due to their lower space requirements and more affordable prices. Understanding the scale is fundamental for collectors, as it influences how the model fits in a display and its overall visual appeal.

Common Scales and Their Differences

Several scales dominate the diecast engine market, each with its unique characteristics and collector base. 1:18 scale is a favorite among enthusiasts who appreciate detail and realism. These models are generally large, allowing for intricate features and often include opening doors, hoods, and detailed engine compartments. 1:24 scale provides a balance between detail and size, being slightly smaller than 1:18 but still offering significant detail and often features working elements. This scale is very popular. 1:43 scale is a staple in many collections, being relatively small and space-efficient, making it ideal for creating extensive displays. These models typically focus on the overall form and general details. Other scales, like 1:64 and 1:12, also exist, each appealing to different collectors based on their preferences for size, detail, and price. The selection of a scale is personal, influencing the collecting experience and the available display options.

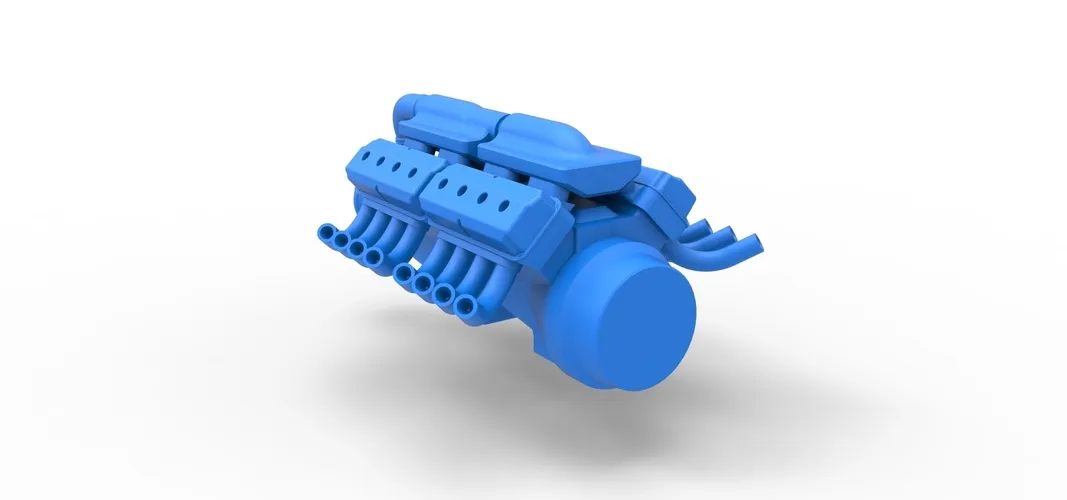

How Scale Affects Detail

Scale directly dictates the level of detail that can be incorporated into a diecast engine. Larger scales permit greater precision in replicating minute details such as the texture of engine components, the intricate design of interiors, and the subtle nuances of paint finishes. The 1:18 scale models frequently feature accurately reproduced engine bays with detailed wiring, plumbing, and even working suspension systems. Smaller scales, while still impressive, may have simplified details due to the limitations of size. In 1:43 scale, the focus shifts to overall shape and proportions, with details such as badges and lights being accurately represented. The scale impacts the number of parts used; larger scale models generally have more individual parts, which adds to the complexity and cost. Thus, the scale chosen by a manufacturer directly influences the level of detail achievable, determining the overall aesthetic appeal and collecting value of the diecast engine.

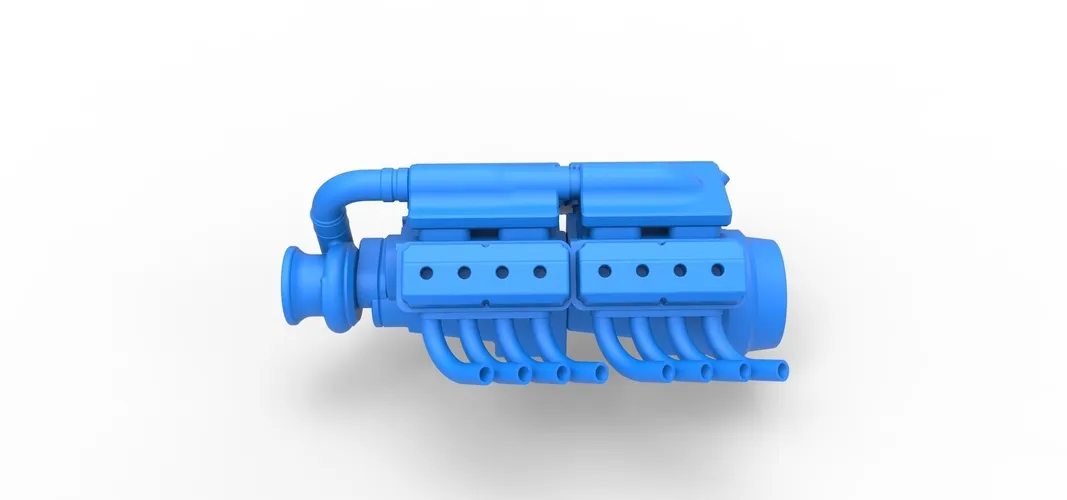

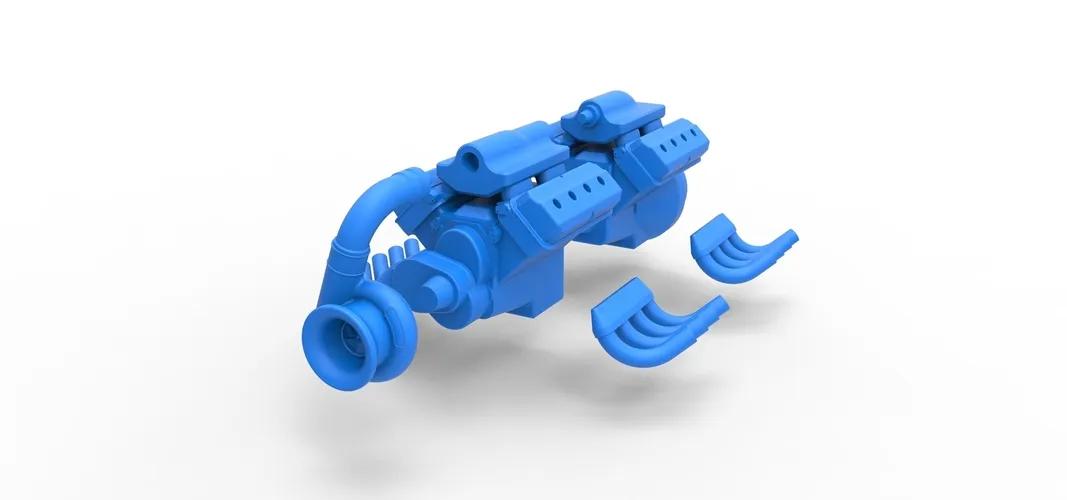

The Manufacturing Process: From Design to Reality

The creation of a diecast engine is a complex process involving meticulous design, precise mold creation, and skilled manufacturing. It begins with detailed designs and blueprints of the real engine or vehicle, which are then translated into 3D models. These models are the basis for the molds used in the die-casting process. The molds, typically made from steel, are intricate and contain the negative impressions of each part of the model. Molten zinc alloy is then injected into the molds under high pressure, rapidly filling the cavities and solidifying to take the shape of the engine components. After cooling, the parts are removed from the molds, and any excess material is trimmed. The parts then undergo cleaning, painting, and detailing, often done by hand, to achieve the final look. The process also includes the assembly of the various components, the application of decals, and quality control checks to ensure each model meets the required standards of accuracy and finish. The manufacturing process reflects a sophisticated blend of technology and craftsmanship.

Die Casting Techniques Explained

Die casting is a crucial technique in the manufacture of diecast engines. The process involves forcing molten metal, typically zinc alloy, into a mold cavity under high pressure. This high-pressure injection ensures that the molten metal fills every intricate detail of the mold, resulting in a high level of accuracy. There are two main types of die-casting methods: hot-chamber and cold-chamber. Hot-chamber die-casting is commonly used for alloys with lower melting points, as the injection mechanism is immersed in the molten metal. Cold-chamber die-casting is used for alloys with higher melting points; the metal is ladled into the chamber separately. The choice of method depends on the material being used. The pressure exerted during die-casting ensures that the metal solidifies quickly, allowing for high production rates and precise replication of detailed designs. The precision of die-casting is fundamental to the creation of intricate engine parts and overall quality of the model.

Painting and Finishing

Painting and finishing are critical steps that transform the raw diecast parts into a realistic and visually appealing model. The process starts with thorough cleaning and preparation of the metal surfaces to ensure proper adhesion of the paint. Various painting techniques are employed, including spray painting and sometimes even hand painting for intricate details. Multiple layers of paint are often applied to achieve a rich and durable finish. High-quality paints that are resistant to chipping and fading are used. The finishing stage also includes the application of decals, such as logos, badges, and markings, which add authenticity to the engine. Clear coats are often applied to protect the paint and decals, enhancing the model’s gloss and shine. The attention to detail in the painting and finishing stages sets the visual appeal of the diecast engine. The skilled application of paint and the precise placement of decals are what bring the miniature engine to life.

The History: A Brief Look at Diecast Engine Origins

The history of diecast engines is a journey through automotive and manufacturing evolution. Diecast models first emerged in the early 20th century, evolving from simple toys to highly detailed replicas. Early models, often made of lead or tin, were primitive compared to today’s standards. The introduction of zinc alloy as the primary material marked a significant advancement, allowing for greater detail and durability. During the mid-20th century, the popularity of diecast models soared. Iconic brands like Dinky Toys and Corgi Toys began producing models that captured the imagination of children and collectors alike. The models were often simpler, but they helped to popularize the diecast industry. Over time, technological advancements in die-casting, painting, and detailing led to the creation of highly accurate and realistic replicas. These models gradually became more sophisticated, attracting collectors who sought detailed and historically significant pieces. The evolution of diecast engines mirrors the advancement of automotive design and the evolution of manufacturing techniques.

Early Diecast Models

The earliest diecast models, dating back to the early 20th century, were rudimentary but marked the genesis of a beloved hobby. These models were typically simpler in design and made from materials such as lead or tin. The focus was less on accuracy and detail and more on creating affordable toys. Early manufacturers such as Tootsietoy were pioneers in the industry. These early models were often crude, with limited moving parts and basic paint schemes. They served as a means of entertainment for children. These early models laid the foundation for the diecast industry, demonstrating the potential of mass-produced miniature replicas of vehicles. Over time, these early models, though simple, have become collector’s items, valued for their historical significance and the insights they offer into the evolution of toy manufacturing.

Evolution of Diecast Engine

The evolution of diecast engines reflects advancements in technology and a growing appreciation for detail and accuracy. The shift from simple metal castings to the introduction of zinc alloys was a major leap, enabling finer detailing and greater durability. The increased use of plastic for various components allowed for more complex designs and features. The rise of detailed painting techniques and the application of decals significantly improved the visual appeal of the models. The incorporation of working features, like opening doors and hoods, and detailed engine bays, added another layer of realism. Modern diecast engines showcase the evolution of manufacturing techniques and aesthetic standards. Today’s models feature accurate proportions, detailed interiors, and finely crafted engine components. This evolution is driven by a growing collector base, who value authenticity and quality, and by advancements in manufacturing and design technologies.

The Collectors: Who Loves Diecast Engines?

Diecast engines attract a diverse community of collectors who share a common passion for automobiles, history, and miniature artistry. Collectors range from casual enthusiasts who appreciate the beauty of the models to serious collectors who seek rare and vintage pieces. The appeal of diecast engines is multifaceted, encompassing an appreciation for automotive design, the history of engineering, and the joy of collecting. Many collectors are drawn to specific car brands, models, or eras. For some, collecting is a way to relive cherished memories or pursue a passion for classic cars. Collectors value the accuracy, detail, and craftsmanship of the models, often spending considerable time researching and curating their collections. The diecast engine community thrives on shared knowledge, the exchange of models, and the mutual appreciation for these miniature automotive masterpieces.

Collecting Communities and Clubs

Collecting communities and clubs play a crucial role in fostering the passion for diecast engines. These communities provide a platform for collectors to connect, share information, and showcase their collections. Clubs often organize meetings, exhibitions, and swap meets, where members can buy, sell, and trade models. Online forums and social media groups further extend the reach of these communities, connecting collectors from around the world. The collector community is a vital source of knowledge, with members sharing information on rare models, manufacturing details, and the history of different brands. The community’s support and the exchange of information enhance the collecting experience and foster a deeper appreciation for diecast engines. These communities provide a valuable space for collectors to connect, share their passion, and deepen their knowledge of the hobby.

What Makes a Diecast Engine Valuable?

The value of a diecast engine is determined by a variety of factors, including rarity, condition, detail, and historical significance. Rare models, limited editions, and those produced in small quantities often command higher prices. The condition of the model plays a crucial role; mint-condition models with original packaging are highly sought after. The level of detail, the accuracy of the replication, and the quality of the finish are also important determinants of value. Models that accurately represent specific vehicles, particularly vintage or historically significant cars, are often more valuable. The brand and manufacturer can influence the value; certain brands have a reputation for quality and detail, which increases their desirability. Collector demand and the availability of the model in the market ultimately influence the price. The combination of these factors determines the value of a diecast engine, making collecting a dynamic pursuit.

Care and Maintenance: Keeping Your Models Pristine

Maintaining the condition of diecast engines is essential to preserving their value and aesthetic appeal. Regular cleaning and proper storage are key practices. Dust is the enemy, so keeping models in a display case or a dust-free environment is crucial. Cleaning should be gentle, using soft cloths or brushes to remove dust and debris. Avoid harsh chemicals that could damage the paint or decals. Proper storage is equally important; storing models in a cool, dry place away from direct sunlight helps prevent fading and deterioration. Displaying models in cabinets or display cases protects them from dust and accidental damage. Taking steps to protect your diecast engine will keep them looking their best and preserve their value for years to come.

Cleaning Techniques for Diecast Engines

Proper cleaning is crucial for maintaining the pristine condition of diecast engines. Begin by gently dusting the model with a soft brush or a microfiber cloth to remove loose particles. For more stubborn grime, a slightly damp cloth with a mild soap solution can be used. Be careful not to soak the model, as this could damage delicate parts or paint. Avoid using abrasive cleaners or harsh chemicals, as they can strip the paint or damage decals. After cleaning, use a dry cloth to remove any residual moisture. Special care should be taken when cleaning detailed areas, like the engine bay or interior, using small brushes or cotton swabs to reach tight spaces. The goal is to keep the model clean and free of dust and grime while avoiding any damage.

Storage Solutions for Your Collection

Proper storage is key to preserving diecast engines over time. Display cabinets and display cases are ideal, providing protection from dust and physical damage. These cabinets also offer an aesthetically pleasing way to showcase a collection. If cabinet space is limited, individual cases or display boxes can be used to protect each model. The storage environment should be cool and dry, away from direct sunlight and extreme temperatures. Exposure to sunlight can cause fading and damage to paint and decals. Avoid storing models in areas with high humidity, which can lead to rust and other forms of degradation. When storing models for extended periods, ensure they are properly supported to prevent any stress on delicate parts. The investment in thoughtful storage solutions preserves the value and appearance of a diecast engine collection.

The Future: What’s Next for Diecast Engines?

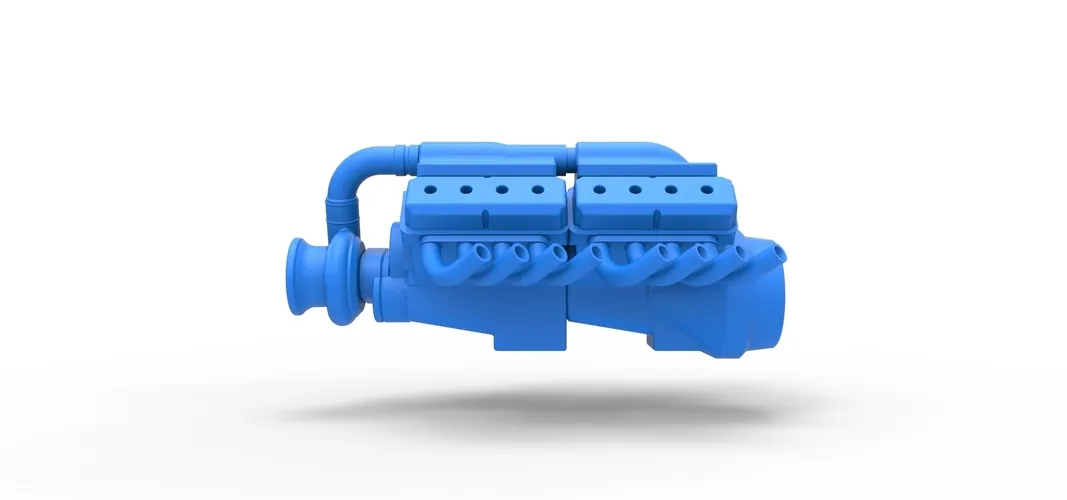

The future of diecast engines promises innovation, increased detail, and a continued appeal to collectors and enthusiasts. Advancements in manufacturing technology, such as 3D printing and precision casting, will enable even more intricate designs and enhanced realism. The use of new materials may lead to models that are more durable and detailed. The integration of technology, such as functioning lights and sounds, could further enhance the collecting experience. Moreover, the continued expansion of the collector base and the growing appreciation for automotive history will fuel demand for new and innovative models. The diecast engine industry is set to evolve, with a focus on accuracy, realism, and innovation to meet the demands of discerning collectors.

Technological Advancements

Technological advancements are poised to revolutionize the diecast engine industry. 3D printing is allowing manufacturers to create highly detailed prototypes and even manufacture certain components, offering a new level of precision and detail. Advances in casting techniques, such as high-pressure die-casting, are leading to more accurate and complex models. The integration of electronic components is also gaining traction, enabling models with functional lights, sounds, and even remote control capabilities. The use of advanced materials, such as new alloys and composite materials, is enhancing durability and realism. These technological innovations are creating a more exciting collecting experience and driving the evolution of diecast engines towards higher levels of detail and functionality. Technological progress is a key factor in shaping the future of the diecast engine industry.

New Trends in Collecting

New trends in collecting are emerging, driven by evolving preferences and technological advancements. There is a growing demand for highly detailed models with exceptional accuracy. Special edition models, limited releases, and collaborations between manufacturers and automotive brands are also becoming increasingly popular. Thematic collecting is gaining traction; collectors are focusing on specific eras, car models, or racing teams. The digital aspect of collecting is growing, with online platforms, social media, and virtual exhibitions playing an increasingly significant role. Moreover, collectors are focusing on sustainability and ethical manufacturing, looking for brands committed to eco-friendly practices. These new trends reflect the dynamic nature of the collecting world and the ongoing evolution of the diecast engine hobby. Collectors are actively seeking unique and engaging ways to celebrate their passion.

In conclusion, diecast engines are a captivating blend of art, history, and engineering. The journey from the materials and manufacturing to the collector’s display is a testament to human ingenuity. The seven astonishing facts presented here only scratch the surface of this detailed world. From the zinc alloy to the manufacturing process, and the communities, these models offer more than meets the eye. The future of diecast engines will only bring further evolution and innovation, solidifying their place in automotive history. Whether you are a seasoned collector or a new enthusiast, the world of diecast engines offers an exciting and rewarding hobby.